Pogopin connector application field

In addition to being widely used in the installation of household appliances in life, Pogopin connectors are also used in military systems such as aerospace, defense and other military systems. It is also a component frequently contacted by electronic engineers. As for its function, it is mainly used to block the circuit. Or between isolated and impassable circuits, bridges of communication are built to allow current to flow, and connectors enable the circuit to achieve predetermined functions. Pogopin connectors are indispensable components in electronic equipment. Observe along the path of current flow. You will find one or more Pogopin connectors. Pogopin connectors should increase diversity and flexibility.

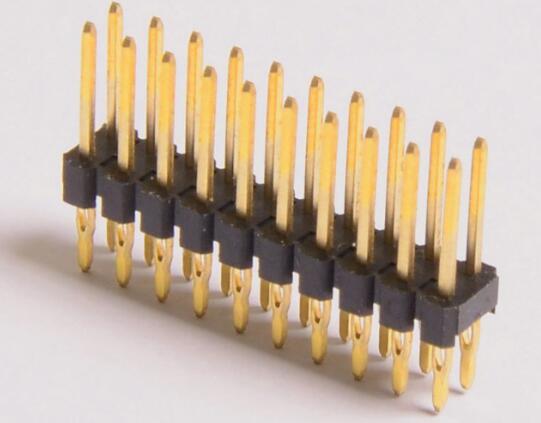

The role of the Pogopin connector cannot be ignored. First, it helps to improve the production process. Its appearance simplifies the assembly process of electronic products and simplifies the mass production process. Secondly, its components are easier to repair. If an electronic component If the component fails, the failed component can be quickly replaced when the Pogopin connector is installed. At the same time, the Pogopin connector is easy to upgrade. Finally, the use of the Pogopin connector can increase the diversity and flexibility of the design. Life is inseparable from electricity. Do not open Pogopin connectors. Pogopin connectors are also called plug-in connectors, sockets and plugs in China. Generally, they refer to electrical Pogopin connectors, which are devices that connect two active devices to transmit current or signals.

First, perform high temperature tests on the failed and normal products, and perform insulation tests on the samples at high temperature and after cooling. The results show that the failed product connector contains a certain amount of moisture, and the presence of water and high temperature will cause the connector to fail. The insulation resistance is reduced, and then the disassembly test of the connector of the lost electronic connector is carried out, and it is found that there are light blue corrosives and a layer of bright metal film attached to the insulation components inside the connector, which fails before and after removing the packaging glue The connector is tested for insulation resistance, and the result shows that the insulation resistance of the failed connector becomes qualified after disassembly and assembly, and the insulation resistance of the packaging glue is normal after testing.

The SEM&E industrial connector DS test was performed on the light blue corrosion products and the bright silver film on the insulating components. The results showed that the light blue corrosion products contained a large amount of zinc (Zn), copper (Cu), and chlorine (Cl), remaining in the red The main element of the bright metal film on the glue is silver (Ag). SEM results show that the microscopic morphology of the metal film is dendritic, which is a typical silver migration performance. The silver migration film and metal corrosion products remain on the insulating components Between the outer metal casing and the inner metal contact strip member, a continuous conductive path between the broken board and the board is formed, which leads to a decrease in the insulation resistance of the connector. The conductive path that has been formed is destroyed in the process of removing the encapsulant, so the connector is blocked. The value returns to normal.

The EDS test was performed on all the metal components of the connector, and the results showed that the metal component integrated with the inner metal contact strip is a copper-zinc alloy with silver plated on the surface, and other metal components are free of copper, zinc, and silver components, so light blue corrosion products and silver migration The film pin headers come from a metal component integrated with the inner metal contact strip. All insulation components are analyzed by infrared. The results show that the insulation components are polyester, silicone, and polyvinyl chloride (encapsulation glue), respectively. Ion chromatographic analysis of the normal product packaging glue shows that the content of chloride ions in the failed product packaging glue is 1.8 times that of the normal product. The presence of chloride ions in a humid environment will greatly promote the corrosion of metal components and ion conduction pathways. Therefore, the reason for the insulation failure of the connector is that the metal component integrated with the inner metal contact strip undergoes corrosion of the main material and migration of the silver plating layer under the promotion of chloride ions under the use of high temperature, humidity, and energization. The products of the two effects adhere to the surface of the insulating component to form a conductive path, thereby reducing the insulation resistance between the outer metal casing and the inner metal contact bar, resulting in insulation failure of the connector.